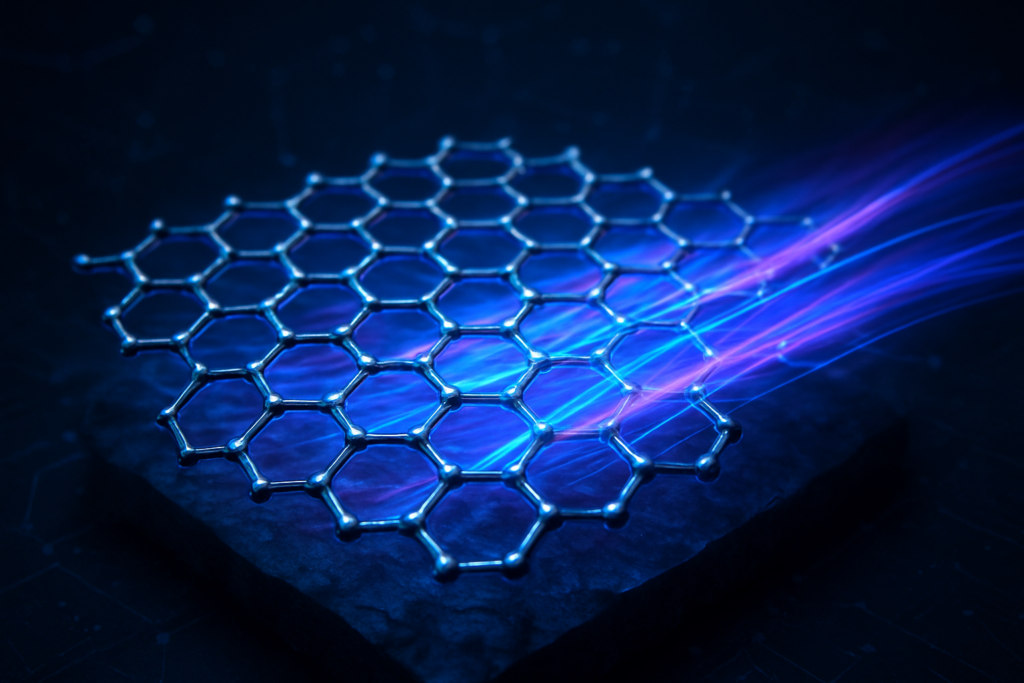

In a milestone that many physicists once deemed impossible, researchers at the Georgia Institute of Technology have successfully created the world’s first functional semiconductor made from graphene. Led by Walter de Heer, a Regents’ Professor of Physics, the team has overcome the "band gap" hurdle that has stalled graphene research for two decades. This development marks a pivotal shift in materials science, offering a viable successor to silicon as the industry reaches the physical limits of traditional microchip architecture.

The significance of this breakthrough cannot be overstated. By achieving a functional graphene semiconductor, the researchers have unlocked a material that allows electrons to move with ten times the mobility of silicon. As of early 2026, this discovery has transitioned from a laboratory curiosity to the centerpiece of a multi-billion-dollar push to redefine high-performance computing, promising electronics that are not only orders of magnitude faster but also significantly cooler and more energy-efficient.

Technical Mastery: The Birth of Semiconducting Epitaxial Graphene

The technical foundation of this breakthrough lies in a process known as Confinement Controlled Sublimation (CCS). The Georgia Tech team utilized silicon carbide (SiC) wafers, heating them to extreme temperatures exceeding 1,000°C in specialized induction furnaces. During this process, silicon atoms evaporate from the surface, leaving behind a thin layer of carbon that crystallizes into graphene. The innovation was not just in growing the graphene, but in the "buffer layer"—the first layer of carbon that chemically bonds to the SiC substrate. By perfecting a quasi-equilibrium annealing method, the researchers produced "semiconducting epitaxial graphene" (SEG) that exhibits a band gap of 0.6 electron volts (eV).

A band gap is the essential property that allows a semiconductor to switch "on" and "off," a fundamental requirement for the binary logic used in digital computers. Standard graphene is a semimetal, meaning it lacks this gap and behaves more like a conductor, making it historically useless for transistors. The Georgia Tech breakthrough effectively "taught" graphene how to behave like a semiconductor without destroying its extraordinary electrical properties. This resulted in a room-temperature electron mobility exceeding 5,000 cm²/Vs—roughly ten times the mobility of bulk silicon (approx. 1,400 cm²/Vs).

Initial reactions from the global research community have been transformative. Experts previously viewed 2D semiconductors as a distant dream due to the difficulty of scaling them without introducing defects. However, the SEG method produces a material that is chemically, mechanically, and thermally robust. Unlike other exotic materials that require entirely new manufacturing ecosystems, this epitaxial graphene is compatible with standard microelectronics processing, meaning it can theoretically be integrated into existing fabrication facilities with manageable modifications.

Industry Impact: A High-Stakes Shift for Semiconductor Giants

The commercial implications of functional graphene have sent ripples through the semiconductor supply chain. Companies specializing in silicon carbide are at the forefront of this transition. Wolfspeed, Inc. (NYSE: WOLF), the global leader in SiC materials, has seen renewed interest in its high-quality wafer production as the primary substrate for graphene growth. Similarly, onsemi (NASDAQ: ON) and STMicroelectronics (NYSE: STM) are positioning themselves as key material providers, leveraging their existing SiC infrastructure to support the burgeoning demand for epitaxial graphene research and pilot production lines.

Foundries are also beginning to pivot. GlobalFoundries (NASDAQ: GFS), which established a strategic partnership with Georgia Tech for semiconductor research, is currently a prime candidate for pilot-testing graphene-on-SiC logic gates. The ability to integrate graphene into "feature-rich" manufacturing nodes could allow GlobalFoundries to offer a unique performance tier for AI accelerators and high-frequency communication chips. Meanwhile, equipment manufacturers like CVD Equipment Corp (NASDAQ: CVV) and Aixtron SE (ETR:AIXA) are reporting increased orders for the specialized chemical vapor deposition and induction furnace systems required to maintain the precise quasi-equilibrium states needed for SEG production.

For fabless giants like NVIDIA (NASDAQ: NVDA) and Advanced Micro Devices, Inc. (NASDAQ: AMD), the breakthrough offers a potential escape from the "thermal wall" of silicon. As AI models grow in complexity, the heat generated by silicon-based GPUs has become a primary bottleneck. Graphene’s high mobility means electrons move with less resistance, generating far less heat even at higher clock speeds. Analysts suggest that if graphene-based logic can be successfully scaled, it could lead to AI accelerators that operate in the Terahertz (THz) range—a thousand times faster than the Gigahertz (GHz) chips dominant today.

Wider Significance: Sustaining Moore’s Law in the AI Era

The transition to graphene represents more than just a faster chip; it is a fundamental survival strategy for Moore’s Law. For decades, the industry has relied on shrinking silicon transistors, but as we approach the atomic scale, quantum tunneling and heat dissipation have made further progress increasingly difficult. Graphene, being a truly two-dimensional material, allows for the ultimate miniaturization of electronics. This breakthrough fits into the broader AI landscape by providing a hardware roadmap that can actually keep pace with the exponential growth of neural network parameters.

However, the shift also raises significant concerns regarding the global supply chain. The reliance on high-purity silicon carbide wafers could create new geopolitical dependencies, as the manufacturing of these substrates is concentrated among a few specialized players. Furthermore, while graphene is compatible with existing tools, the transition requires a massive retooling of the industry’s "recipe books." Comparing this to previous milestones, such as the introduction of FinFET transistors or High-K Metal Gates, the move to graphene is far more radical—it is the first time since the 1950s that the industry has seriously considered replacing the primary semiconductor material itself.

From a societal perspective, the impact of "cooler" electronics is profound. Data centers currently consume a significant portion of the world’s electricity, much of which is used for cooling silicon chips. A shift to graphene-based hardware could drastically reduce the carbon footprint of the AI revolution. By enabling THz computing, this technology also paves the way for real-time, low-latency applications in autonomous vehicles, edge AI, and advanced telecommunications that were previously hampered by the processing limits of silicon.

The Horizon: Scaling for a Terahertz Future

Looking ahead, the primary challenge remains scaling. While the Georgia Tech team has proven the concept on 100mm and 200mm wafers, the industry standard for logic is 300mm. Near-term developments are expected to focus on the "Schottky barrier" problem—managing the interface between graphene and metal contacts to ensure that the high mobility of the material isn't lost at the connection points. DARPA’s Next Generation Microelectronics Manufacturing (NGMM) program, which Georgia Tech joined in 2025, is currently funding research into 3D Heterogeneous Integration (3DHI) to stack graphene layers with traditional CMOS circuits.

In the long term, we can expect to see the first specialized graphene-based "co-processors" appearing in high-end scientific computing and defense applications by the late 2020s. These will likely be hybrid chips where silicon handles standard logic and graphene handles high-speed data processing or RF communications. Experts predict that once the manufacturing yields stabilize, graphene could become the standard for "beyond-CMOS" electronics, potentially leading to consumer devices that can run for weeks on a single charge while processing AI tasks locally at speeds that currently require a server farm.

A New Chapter in Computing History

The breakthrough in functional graphene semiconductors at Georgia Tech is a watershed moment that will likely be remembered as the beginning of the post-silicon era. By solving the band gap problem and demonstrating ten-fold mobility gains, Walter de Heer and his team have provided the industry with a clear path forward. This is not merely an incremental improvement; it is a fundamental reimagining of how we build the brains of our digital world.

As we move through 2026, the industry is watching for the first results of pilot manufacturing runs and the successful integration of graphene into complex 3D architectures. The transition will be slow and capital-intensive, but the potential rewards—computing speeds in the terahertz range and a dramatic reduction in energy consumption—are too significant to ignore. For the first time in seventy years, the throne of silicon is truly under threat, and the future of AI hardware looks remarkably like carbon.

This content is intended for informational purposes only and represents analysis of current AI developments.

TokenRing AI delivers enterprise-grade solutions for multi-agent AI workflow orchestration, AI-powered development tools, and seamless remote collaboration platforms.

For more information, visit https://www.tokenring.ai/.