- Lyten is further securing its battery supply chain by locally manufacturing its own battery grade lithium-metal alloys and foils, creating an entirely U.S. manufactured anode supply chain.

- Lyten’s Lithium-Sulfur battery eliminates the need for foreign sourced critical minerals, making it a locally sourced, locally manufactured, tariff free alternative to lithium-ion batteries.

- Since 2023, Lyten has manufactured its Lithium-Sulfur batteries, including its cathodes and anodes, in the U.S., in stark contrast to traditional lithium-ion batteries where only 2% of cathodes and anodes are manufactured in the U.S.

Lyten, the supermaterial applications company and global leader in lithium-sulfur batteries, announced today it has produced the United States’ first battery grade lithium-metal foil utilizing U.S. made lithium alloys and U.S. sourced lithium-metal. Lyten has already achieved a fully localized supply chain for its sulfur cathode and is now localizing the supply chain for its lithium-metal anode, creating a supply chain resilient and tariff-free battery. Applications for Lyten’s ultra-lightweight batteries include energy storage, EVs, drones, satellites, micromobility, and defense.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20250416247241/en/

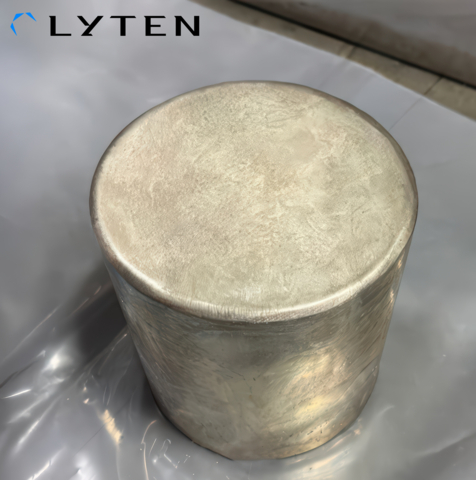

Lithium metal alloy ingot, produced by Lyten as input into its US made anodes for lithium-sulfur batteries.

This domestic manufacturing milestone for battery grade lithium-metal comes at a time when U.S. policymakers and defense agencies are actively pushing for greater domestic sourcing of critical materials and the establishment of a US battery industry. Today, batteries and the required critical minerals supply chain predominately come from China, creating a critical vulnerability for the U.S.

Dan Cook, Lyten Co-Founder and CEO stated, “To build a U.S. battery industry, we must solve the supply chain challenge. We have already eliminated the need for nickel, manganese, cobalt, and graphite with our Lithium-Sulfur battery, allowing us to focus on local supply and production of lithium. Lyten will be the only battery manufacturer in the U.S. shielded from tariffs and critical minerals risk.”

Lyten Lithium-Sulfur is made from widely available and geographically dispersed materials that can be sourced and manufactured in the United States. Lyten has replaced mined minerals like nickel, manganese, cobalt, and graphite with a sulfur cathode and lithium-metal anode. Sulfur is abundantly available worldwide as an environmentally friendly byproduct of multiple global industries, including oil & gas, mining, and chemicals manufacturing. At present, the vast majority of battery grade lithium is processed and manufactured in China.

“Lithium is abundantly available across the United States, but the capacity to process lithium into battery grade materials is extremely limited in the U.S. Being able to design and process our own lithium-metal alloys and foils is a game changer and puts Lyten at the front edge of U.S. battery manufacturing, especially for next generation Lithium-Sulfur battery technology,” said Celina Mikolajczak, Lyten Chief Battery Technology Officer.

Lyten is addressing two critical steps in the lithium supply chain. First, Lyten has begun production of proprietary lithium alloys with the help of Creative Engineers, Inc. in New Freedom, Pennsylvania. The companies collaborated to design and build the lithium metal alloy ingot manufacturing equipment and Lyten is sourcing its lithium-metal feedstock from a facility in the Eastern U.S.

Second, Lyten is converting lithium alloys into proprietary lithium-metal foils in custom built extrusion and rolling equipment in its San Jose, California manufacturing facility. Lyten’s lithium foil extrusion and rolling capacity is one of the largest in North America, and the foils drop directly into Lyten’s lithium-sulfur battery manufacturing lines in California.

Lyten is producing National Defense Appropriations Act (NDAA) compliant lithium-sulfur battery cells in San Jose, California. Lyten recently announced the acquisition of Northvolt’s battery manufacturing plant in San Leandro, California to quickly scale production to meet the demand for American made batteries.

In December 2024, Lyten and the Export Import Bank of the US announced a $650M LOI to fund the scale up and delivery of Lyten Lithium-Sulfur for battery energy storage systems. Additionally, in 2024, Lyten announced its integration into Chrysler’s Halcyon Concept electric vehicle, plans to integrate lithium-sulfur into AEVEX Aerospace’s unmanned aerial vehicles, and the selection of Lyten Lithium-Sulfur for demonstration on-orbit aboard the International Space Station (ISS), scheduled for launch later in 2025.

About Lyten

Lyten, founded in 2015, is a supermaterial applications company that has received more than $425 million in equity investment. Lyten has built a proprietary materials platform, called Lyten 3D Graphene, that it uses to build better performing, lower cost, and decarbonizing products. Lyten is currently commercializing next-generation lithium-sulfur batteries for use in energy storage, transportation, aerospace, space, consumer electronics, and defense markets; next-generation high strength, low carbon footprint composites; and next-generation sensors that significantly increase detection sensitivity and selectivity for use in environmental, automotive, industrial, health, and supply chain applications.

The company lists more than 510 patents granted or pending and is currently manufacturing Lyten 3D Graphene material, lithium-sulfur batteries, and other products in San Jose, California. Lyten was named Fast Company’s #8 Most Innovative Energy Company and named one of America’s Top Green Technology Companies by Time in 2024 and one of the World’s Top Green Technology Companies by Time in 2025.

View source version on businesswire.com: https://www.businesswire.com/news/home/20250416247241/en/

Contacts

Bob Zeitlinger

bzeitlinger@makovsky.com

551-427-7298