Smart Weigh Packaging Machinery Co., Ltd. (“Smart Weigh”), a global leader in intelligent weighing and packaging systems, continues to push boundaries in food manufacturing automation with its advanced line of Industry 4.0-ready packaging solutions. From multihead weigher packing systems to fully automated ready-meal packaging lines, Smart Weigh stands as a trusted partner for precision, reliability, and technological innovation.

A Decade of Innovation and Global Growth

Smart Weigh started its operations in 2012, establishing its base in a 1,000-square-meter facility to create its first combination multihead weigher and check weigher. The company reached its first major achievement when it developed its linear scale during 2013 which led to its transition from equipment production to complete system solution delivery.

The company achieved a major breakthrough between 2014 and 2016 through its linear combination scale development which united traditional stability with combination-scale operational efficiency. The company established its position as a worldwide packaging solutions provider through its 2017 move to an 8,000-square-meter production facility which enabled the creation of customized production lines for clients.

Today, Smart Weigh employs 90 skilled workers who maintain service centers across Indonesia Dubai Spain and the United States while planning to establish a new facility in Indonesia for 2025. Hanson Wang who leads Smart Weigh as CEO stated that the company exists to provide technological solutions which directly support food manufacturing operations. Our combination of automation systems with data intelligence and advanced engineering enables customers to boost their production rates while achieving better accuracy levels.

Industry 4.0 Technology for the Future of Food Manufacturing

The snack industry undergoes rapid transformation under Industry 4.0 because manufacturers need data analytics and automated systems to achieve operational excellence. Smart Weigh designed its Industry 4.0 Snack Weighing Packaging Line to fulfill the changing requirements of modern manufacturing. The system operates at 200 packs per minute with precise accuracy for various snack types including both fragile chips and sticky candies through its advanced control system and predictive maintenance and real-time optimization features.

The system automatically stores product profiles for automatic recognition which enables it to set the best parameters for each production batch. The automated system prevents human mistakes while reducing production stoppages when switching between different snack products especially useful for seasonal or limited-edition snack items.

“Industry 4.0 allows us to go beyond basic automation,” added Wang. “Our machines can think, adapt, and optimize, delivering smarter, more connected manufacturing ecosystems.”

Compact Power: The Multihead Weigher Duplex VFFS Packing Line

The Multihead Weigher Duplex Vertical Form Fill Seal (VFFS) Packing Line from Smart Weigh represents a leading innovation which operates at Industry 4.0 standards to produce 200 packs per minute within a small footprint. The vertical design of this system enables efficient operation in limited manufacturing areas while keeping production space requirements minimal.

The system operates at high-speed production with dual VFFS operation and smart vibration control and real-time combination algorithms to maintain precise weighing results. The system's modular design streamlines installation processes and its predictive maintenance functions reduce equipment breakdowns.

The 20-head multihead weigher operates continuously through 24/7 operations with automated product changeovers and remote diagnostic functions that enable one operator to handle complex production lines.

Duplex Pouch Packing Machine: Dual Efficiency in Action

The Duplex 8-Station Rotary Premade Pouch Packing Machine from Smart Weigh sets new standards for both speed and dependability in production operations. The system operates at 100 packs per minute by processing two pouches per automated cycle through its dual-lane design which provides seamless pouch handling from feeding to sealing and coding.

The 4.5-ton heavy-duty construction provides operational stability and the system uses dual zipper opening systems with 16 or 24-head multihead weighers to achieve precise measurements for snack and nut and confectionery products. The system design minimizes production floor space requirements while meeting EU CE and US UL safety standards and allows users to select from various packaging options including coding and nitrogen flushing and vacuum sealing for enhanced operational efficiency with preserved product quality.The modern food production industry depends on Ready Meal Packaging Machines which operate as complete automated systems.

The Smart Weigh Automatic Ready Meal Packaging Machine delivers complete weighing and filling and sealing functionality for the expanding ready-to-eat market segment. The system maintains freshness through vacuum tray sealing and gas flush modified atmosphere technology while it optimizes tray management and labeling operations.

The packaging line operates at speeds between 1,000 to 1,500 trays per hour which results in reduced personnel needs and faster production times. The system operates with advanced sensors to detect trays and measure quantities and cut films which enables it to process different food packaging types including vegetable trays and cooked meals with high precision and consistent results.

A Comprehensive Advantage Over Competitors

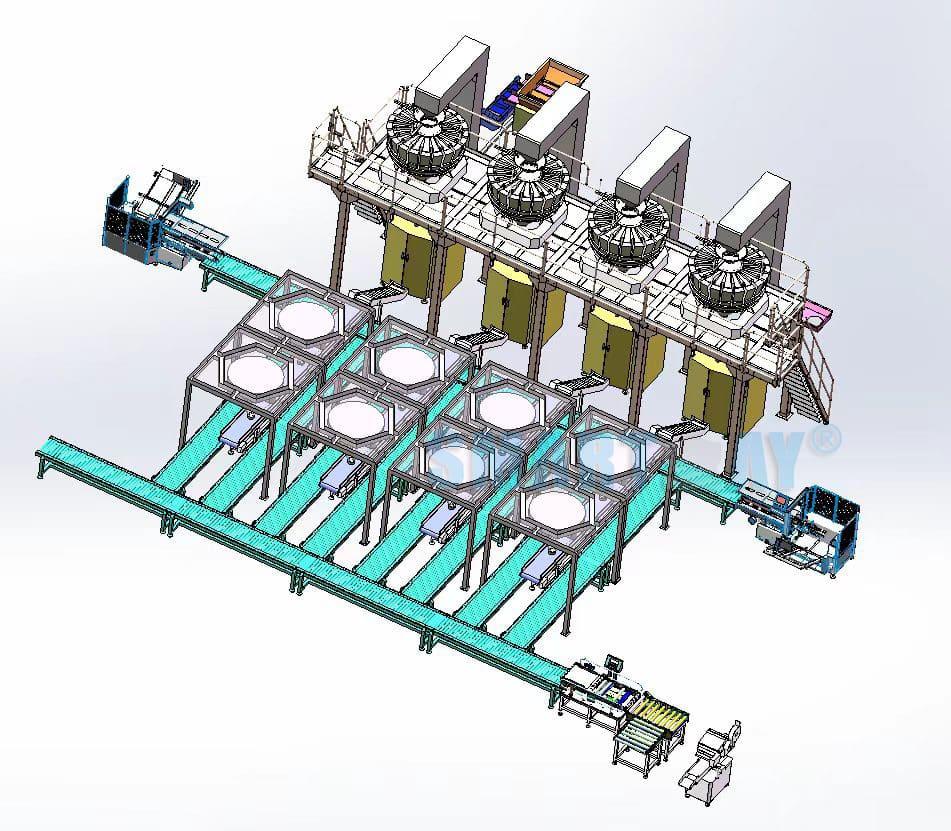

Smart Weigh provides complete automation solutions that include feeding and weighing functions and filling and packing and labeling and carton packing and palletizing operations. The company designs each project based on the specific requirements of the client's production facility and plant layout. The complete system design enables all components to work harmoniously with their environment which leads to better investment returns and simplified operations.

The company provides global service accessibility through its strategically located service centers in major international markets which deliver fast response times and reliable post-purchase assistance.

A Future Focused on Innovation and Customer Success

As Smart Weigh approaches its next phase of growth, its focus remains on research-driven development and smart factory integration. The engineering teams at Smart Weigh maintain their focus on developing automation systems which unite physical manufacturing with digital intelligence to help producers achieve better sustainability and operational efficiency and market competitiveness.

“Our vision is to make packaging smarter and simpler for every client,” concluded Hanson Wang. “We’re not just selling machines; we’re building intelligent ecosystems that help businesses thrive in an increasingly connected world.”

About Smart Weigh Packaging Machinery Co., Ltd.

Smart Weigh Packaging Machinery Co. Ltd established its operations in 2012 to become a worldwide leader in designing and manufacturing multihead weighers and linear weighers and check weighers and metal detectors and complete weighing and packing line solutions. Smart Weigh operates from Zhongshan City in Guangdong Province China while maintaining regional centers in Indonesia Dubai Spain and the USA to serve international clients. The company drives food packaging automation progress through its commitment to innovative solutions and precise engineering and active customer partnerships.

For more information, please visit: https://www.smartweighpack.com/

Media Contact

Company Name: Smart Weigh Packaging Machinery Co., Ltd.

Contact Person: Hanson Wong

Email: Send Email

Country: China

Website: www.smartweighpack.com